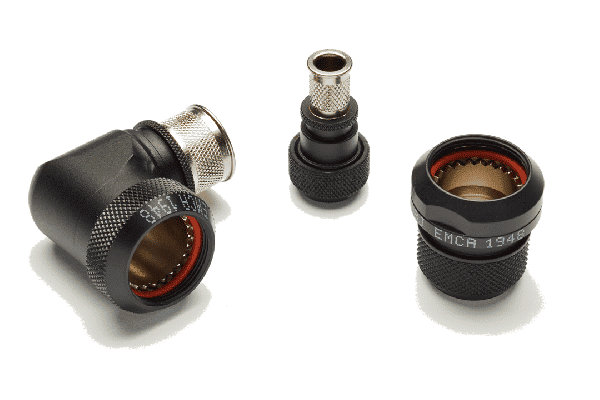

Connector backshells, adapters, protective covers, cable clamps and other accessories from leading trusted OEM’s including EMCA, Amphenol, Glenair, Compaero, Telason and TE.

The adapters range from simple strain relief’s to submersible EMI/RFI shielded backshells for use in harsh environments.

To safeguard connectors whilst they are not in use we provide protective covers with a wide range of lanyards, eyelets and security rings enabling complete customisation. Our line of MS3057 cable clamps are extensively used in automotive and heavy industrial markets and are available in a multitude of finishes.

Looking for the right backshell for your connector?

Connector Backshells

Shrink Boot Adapters

Shrink boot adapter backshells are an effective way to terminate shielded or un-shielded cable, by using heat-shrink boots. If using shielded cable, the shield can be terminated onto the backshell by use of a constant force spring or band, before the boot is applied. Using the heat shrink boot is a way of providing environmental protection and strain relief to cable termination and gives the benefit of repairability.

Non-Environmental Backshells

Non-Environmental connector backshells are used when there is a requirement for additional space between the rear of the connector and the strain relief. This allows for cable service loops, jumping, filter networks, etc. They provide mechanical strain relief for non-environmental applications.

Environmental Backshells

Environmental connector backshells protect the wiring side of the connector from dust, dirt, moisture and fluids. Almost all recent Military specification circular connectors are designed so that when the wires are inserted through the grommet the connector will be environmentally sealed once the backshell or strain relief is secured (assuming all holes in the grommet contain either a wire or a sealing plug).

EMI/RFI Non-Environmental Backshells

Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) are both causes of signal interference. When strong external noise fields exist the conductors of a cable act as antennas and pick up the radiated signals. The reception of this interference results in inaccurate or interrupted data transmission. An effective shield prevents the reception of undesired signals as well as confining extraneous signals generated to within the cable itself.

EMI/RFI backshells enclose the cable in a tightly woven metal braid comprised of wire strands. This is then terminated at one or both ends of the cable to ground potential. The termination and grounding of the shield is accomplished by using a suitable connector backshell. A variety of backshell configurations are available for termination of cable shielding

EMI/RFI Environmental Backshells

Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) are both causes of signal interference. When strong external noise fields exist, the conductors of a cable act as antennas and pick up the radiated signals. The reception of this interference results in inaccurate or interrupted data transmission. An effective shield prevents the reception on undesired signals as well as confining extraneous signals generated within the cable itself.

EMI/RFI Backshells enclose the cable in a tightly woven metal braid comprised of wire strands which is then terminated at one or both ends of the cable to ground potential. The termination and grounding of the shield is accomplished by using a suitable connector backshell. A variety of backshell configurations are available for termination of cable shielding

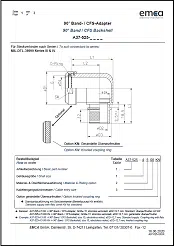

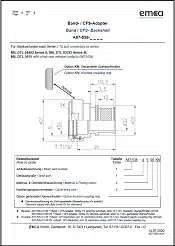

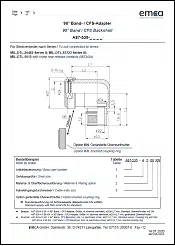

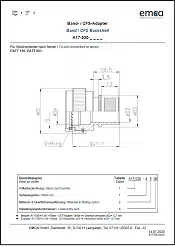

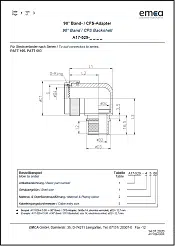

AS85059 (M85049) Backshells

Backshells for Military and Aerospace applications are governed by the SAE and the now ratified AS85049 standard. All existing M85049 documents have been superseded by the new standard. AS85049 backshells are coupled to the rear of the connector body to support and strain relieve the cable entry to the rear of the connector. Strain relief clamps are available in either straight or 90 degree variants. Coupling is either self-locking or non self-locking.

Connector Accessories

M85049/128 Termination Bands for use with circular adapters

We provide Government QPL manufactured M85049/128 Termination Bands. These bands are commonly used to attach a braid or a shield to a backshell to provide EMI/RFI shielding. They are available in different lengths, widths, and styles. Our Termination Bands work seamlessly with Daniels Tooling.

MS3057 Style A, B, C & D Cable Clamps

Our MS3057 style cable clamps have MS ‘V’ threads that will provide strain relief for MIL-DTL-5015 Solder (style A) connectors. These clamps are used in the automotive and heavy industrial markets. They are available in a wide range of finishes including Cadmium Olive Drab, Electroless Nickel, Black or Green Zinc Cobalt and more.

MS3420 Bushings (with flange)

Bushing of synthetic rubber to be used with cable clamps for protection of the cable or wires. Generally for use with MS3057 Clamps.

Protective Covers for Circular Connectors

Our full line of protective caps / sealing caps provide moisture and dust protection for almost every circular mil-spec connector. Available with a wide selection of lanyard types and lengths. Security rings and eyelets of all sizes are also available.

Constant Force Spring Adapter

We can provide a unique re-enterable termination system for connecting a cable shielding braid to a circular connector. When used in conjunction with a heatshrink moulded shape, a sealed environmental termination system is achieved. The main feature is that the termination can be re-entered when required. It is thereby possible to effect repairs to connector pins/sockets without the need to discard any part of the shielding system. Due to the self-tensioning nature of the spring, it provides excellent resistance to vibration and shock. Predominantly used in the Aerospace, Defence and professional electronics sectors.

Did you know?

Your project will not be complete or meet the requirements of your end customer specifications unless they are provided with the correct compatible connector accessories.

Don’t forget to ask Apollo Aerospace Components to define and quote the correct circular connector backshell and accessories for your application.

What is a connector backshell?

A backshell is an accessory that is fitted to the rear of a connector to reduce strain at the interface between the cable wires and the connector contacts and to terminate the cable shield. It is normally a separate component from the connector, although some connectors are available with an integrated solution. They typically secure the cable via a clamp, gland or shrink boot.

There is variation in the size and type of backshells to accommodate different types of cable and for compatibility with the type and size of connector. There are various sized openings to accept the diameter of the wire or cable. Dependent on connector type a wire sealing grommet may also be supplied.

Environmental protection

Backshells are available with varying degrees of environmental protection ranging from a simple strain relief clamp to a fully sealed EMI/RFI protected product. Straight, 90 degree or 45-degree outlets are available to suit the connector type and application.

When using shielded cable, the backshell will have provision to connect the shield, thereby offering an earth path through the backshell to the connector.

Materials and finishes

Backshells are produced from various materials and the correct choice will be dependent on the connector type and the application they are being used for.

These materials include Aluminium, Stainless Steel, Nickel Aluminium Bronze and even plastic or composite materials. These materials are available with finishes such as Cadmium Olive Drab, Electroless Nickel, Zinc Nickel, Hybrid Finishes and Anodizing.

The choice of finish will depend on the connector the product is fitted to and the environmental requirements. Selection of the right product begins with the need to identify the application, based on how the end to end interconnect solution will be used. Factors to define the type of backshell required include:

- Exposure to dirt, moisture, electrical or radio interference

- Connector type (range, style, size, shape)

- Cable diameter size

- Shielded or Non-shielded cable

- Shape or cable routing restrictions

- Performance specification and requirements i.e. MIL SPEC, EMI, RFI, etc.

Classifications

Based on the connector type, system design and application demands the best product will be selected from one of the following groups:

Non-Environmental: Will be used where no harsh environment will be present (dust, dirt, moisture, fluids, salt.) Suitable for an inside the box/climate-controlled room application or where there is a requirement for additional space between the rear of the connector and the strain relief to allow for cable service loops, etc.

Environmental: Will be used in a harsh environment (dust, dirt, moisture, fluids, salt, temperature extremes.) Most common military specification cylindrical connectors are designed so that they will be environmentally sealed once the backshell or strain relief is secured.

Non-Environmental EMI/RFI: Will be used in an area susceptible to the reception of Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) where no harsh environment will be present (dust, dirt, moisture, fluids, salt.) EMIs and RFIs originate from coils, electromagnets, electric motors, transformers, fluorescent lighting, high power radar, broadcast stations and other communications circuits.

Environmental EMI/RFI: Will be used in a harsh environment (dust, dirt, moisture, fluids, salt) area susceptible to the reception of Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI.) EMIs and RFIs originate from coils, electromagnets, electric motors, transformers, fluorescent lighting, high power radar, broadcast stations and other communications circuits.