Conesys D38999 Series III circular connectors are high-performance cable to panel interconnects making them suitable for military, aerospace and harsh environment applications.

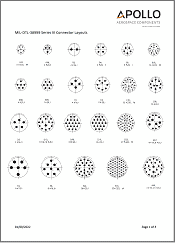

The Conesys MIL-DTL-38999 Series III range of military connectors (commonly known as D38999 III) features a number of body styles, contact termination options, body materials and platings. Consequently, these connectors suit a wide variety of electronic, mechanical and environmentally demanding applications. Up to 128 contacts are available in a number of defined high-density insert arrangements with a reliable tri-start coupling.

Price and delivery

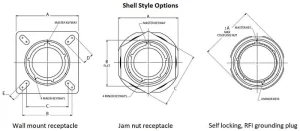

We stock a wide range of shell styles (Plugs & Receptacles), in all shell sizes, in all plating’s (including Cad Olive Drab, Black Zinc Nickel, Electroless Nickel etc) along with a wide range of contact layouts.

Contact us now for fast turnaround in 48 hours from receipt of order.

QPL listed Assembling Distributor for Conesys

Apollo Aerospace Components assembly facility is fully approved to AS9100 Rev D, AS9120 Rev B and ISO9001 2015 and is QPL listed as an Assembling Distributor for Conesys (Aero Electric Connector, Inc). Therefore, we can assemble MIL-DTL-38999 III connectors to meet your specific requirements with fast turnaround available.

Apollo is also approved by Conesys as a value-add assembling distributor for VG95319-1006, 1007 & 1008 connectors, the VG approved MIL-DTL-38999 Series III connector.

Fast turnaround of finished product is available from an extensive UK stock holding ensuring shortest delivery times, best price and no minimum order quantity of approved product.

Features

- Scoop proof crimp contacts

- Tri-start mating thread

- Full mate indicator

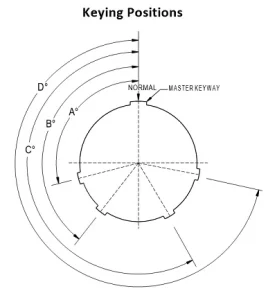

- Keying options

- Extensive range of insert arrangements

- Operating temperatures: -65°C to +200°C

- EMI shielding to 65dB minimum at 10 GHz

Benefits

- High density in a rugged package

- Reliable fast mating

- Self locking with visual confirmation

- Improved shielding compared to bayonet variants

- Shell to shell bottoming

- Wide range of accessories

D38999 Datasheets

Quality Approvals

Integrated Backshell D38999 Connectors

These connectors offer the performance advantages of D38999 with the following benefits over a traditional connector/backshell pairing:

- quicker assembly;

- space saving;

- lower weight;

- time-saving during ordering;

- reduced inventory holding.

The one-piece shell construction completely integrates the straight backshell thereby enabling screen termination using either band or spring. They are manufactured in both aluminium and stainless steel with various plating options available, including Black Zinc Nickel across the 3 shell styles.

Accessories

Need accessories? These circular connectors can be ordered with a very broad range of compatible accessories, be it a simple strain relief clamp, a fully sealed RFI/EMI compatible backshell or a custom design, thereby enabling Apollo to meet the most demanding project requirements.

Apollo Aerospace Components stock a comprehensive range of circular connector backshells and protective caps (D38999-32 and D38999-33) from EMCA Electro-mechanic to suit the customers’ specific requirements.

For more information contact the team or visit the relevant product page.