MIL-DTL-38999 connectors are high-performance cable to panel interconnects that are suitable for military, aerospace and harsh environment applications.

They are available with high-density insert arrangements that are capable of supporting up to 128 contacts across a variety of terminations within four main body and mating styles (series I, II, III and IV). For more information about 38999 connector series differences please refer to the Style Variants that are described below. Apollo also supplies JN1003/VG96912 connectors known as “Series 1.5”.

MIL-DTL-38999 connectors feature a number of Product Options covering shell sizes, couplings, contact termination options, body materials and platings. Consequently, this series of circular connectors are suited to a very wide range of electronic, mechanical and environmentally demanding applications.

Please contact us for unbiased specialist advise. We can quickly assemble fully approved MIL-DTL-38999 Series 3 from Amphenol and Conesys to meet your specific requirements or supply from a number of our trusted OEM’s. As a result, Apollo are able to source the best solution to meet both your application and scheduling needs.

Style Variants

MIL-DTL-38999 Series 1

- Description: Scoop-Proof 3-Point Bayonet Coupling

- Coupling: Bayonet coupling; quick disconnect; positive locking, keyed

- EMI Shielding: 40 dB minimum at 10 GHz

- Mating Speed: 120° or 1/3 turn to full mate

MIL-DTL-38999 Series 2

- Description: Low-Profile 3-Point Bayonet Coupling

- Coupling: Bayonet coupling design, quick disconnect, captive, keyed

- EMI Shielding: 40 dB minimum at 10 GHz

- Mating Speed: 120° or 1/3 turn to full mate

MIL-DTL-38999 Series 3

- Description: Scoop-Proof, Triple Start, Self-Locking

- Coupling: Triple-start threaded coupling design, rapid advance, self-locking and full-mate indicator, keyed

- EMI Shielding: EMI shielding to 65dB minimum at 10 GHz

- Mating Speed: 360° or one full turn to full mate

- Operating Temperature Range:

- Classes F, K, S and BZ*: -65°C to +200°C (-85°F to +392°F)

- Classes W, T, Z, BN* and ZC*: -65°C to +175°C (-85°F to +347°F)

Download: Datasheet MIL-DTL-38999, SERIES III Connectors

MIL-DTL-38999 Series 4

- Description: Scoop-Proof, Breech Lock

- Coupling: Breech lock coupling design, rapid advance, self-locking, keyed

- EMI Shielding: 65 dB minimum at 10 GHz. Grounding before engagement of contacts

- Mating Speed: 90° or 1/4 turn to full mate

D38999 Series 3 – Value add assembly

Assembly facility for MIL-DTL-38999 Series III approved to AS9100.

Contact us today for a fast turnaround to your requirements.

Product Options

Couplings:

Contacts:

Contact Arrangements:

|

Body Platings:

Special variants:

|

M39029 Contacts

Mil Spec contacts for MIL-DTL-38999 Series III Circular Connectors

- Termination:

- Crimp

- Contact Material:

- Copper alloy

- Plating:

- Gold

- Identification:

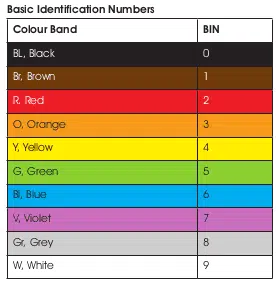

- Industry standard colour band or BIN identification

- Related Products:

- M39029 power contacts with reduced or expanded crimp barrels

Thermocouple contacts

- M39029 power contacts with reduced or expanded crimp barrels

- Accessories, including:

- Sealing Plugs

- Contact Seal Boots

- Dummy Contacts

- Tools for crimping to wire or cable

- Tools for insertion to and extraction from the connector body

Basic Identification Numbers (BIN#)

The three identification colour bands are marked around the contact at the wire barrel end and are positioned as follows:

- Band 1 is closest to the wire entry point of the contact

- Band 3 is closest to the mating end of the contact

- Band 2 is between band 1 and 3

Original Equipment Manufacturers have the option of stamping the BIN# on the contact for size 16 and larger.

AS85049 backshells

Material Options:

- Aluminium

- Stainless Steel

Plating Options:

- Cadmium Olive Drab over Electroless Nickel

- Aluminium

- Black Anodize

- Electroless Nickel

Variants:

- Straight or 90 degrees

- Self-locking or non self-locking

Did you know?

There is an industry move away from the use of hazardous materials such as Cadmium, which is driven by the requirements of RoHS. For this reason mil spec 38999 connectors are available with Black Zinc Nickel plating. This conductive and non-reflective black finish is approved for 500 hrs salt spray endurance and is fast becoming the new defence industry standard.

Please contact us at Apollo and we will advise and recommend alternative RoHS compliant products and their availability.

If you are interested in the history and development of MIL-DTL-38999 please read our article here.